What is the reason of the choice of laser cutting machine

Now laser cutting machine application market is getting more and more attention, especially in the field of mechanical processing. Laser cutting machine what advantage? Get the attention and favor of so many enterprises? This is all the more interested in the topic, let us to explain the choice of laser cutting machine is what reason.

Application status of laser cutting machine

Since the laser invention will gradually be applied to various fields, including audio equipment, location, medical equipment, industrial processing, especially used in industrial manufacturing field is particularly widespread. Although the laser transmitter is very expensive (hundreds of thousands to millions), but because of the laser processing with traditional processing There is nothing comparable to this advantage, in laser processing has accounted for more than 50% share of the industrial processing industry.

The processing characteristics of laser cutting machine

The laser itself belongs to high brightness, directional accuracy, laser beam of monochromatic and parallel coherent light source, and the energy density is very high. When the focused laser beam can produce high temperature in the irradiated materials. In the tens of thousands of degrees high temperature under the action of the material, no matter how hard will instantly melting and evaporation, while generating shock waves, to melt materials removal.

During laser materials processing, essentially causing local heating melting vaporizing material. The biggest characteristic of the laser processing technology is no mould can be processed by laser cutting machine, blanking out of a lot of mold, the production time and production cost decrease, better in the market to take advantage of, is very conducive to a variety of small batch production, mass production and after.

The future development direction of laser cutting machine

Now laser cutting technology in the domestic market is not very mature, the future is mainly by high power, high brightness for the first development direction. Solid state laser has been completed kilowatts of power. While the new plasma cutting two kinds of method and laser cutting. Laser cutting is the most outstanding, especially the laser cutting machine laser cutting machine and stainless steel laser cutting machine is not only high cutting speed, high efficiency, low processing cost, and quality is better than much of plasma cutting. Second main direction of development, to play a greater role, laser industry in the direction of the existing development, low price, mass production, improve performance. Notable is, semiconductor laser, and it can improve the efficiency, increased from 4 to 7, 80%, 50%.

It can improve the brightness. The third is the industrialization is consistent, into the industrial mass production.

Choose the ten big reason for laser processing

(1) using precision worktable can fine processing.

(2) the use of micro system or camera system, can be observed or monitoring on the machined surface condition.

(3) can pass through the transparent material (such as quartz, glass), for the processing of the internal parts.

(4) can be processed on the vast majority of metal or non-metal materials.

(5) the laser beam is fine, the processed material consumption is very small.

(6) in laser processing, won’t produce X ray image processing methods such as electron beam bombardment, interference will not be affected by the electric and magnetic fields.

(7) linewidth of these signs can be as small as 12Mm, line depth of up to 10Mm, so it can mark the part surface on the millimeter level “size”.

(8) laser is a non mechanical “tool” for processing, the material does not produce mechanical extrusion or stress, no “tool” wear, rarely cause environmental pollution.

(9) can use the prism, a reflector system (Nd:YAG laser can be used for fiber optics) beam will be gathered to the inner surface of the work piece or inclined surface processing.

(10) has the advantages of simple operation, the use of computer numerical control technology to realize automatic processing, can be used in the production line for the high speed and high efficiency machining of parts, can be used as part of a flexible manufacturing system.

Need Help!!!

Categories

Recent Post

Tag Cloud

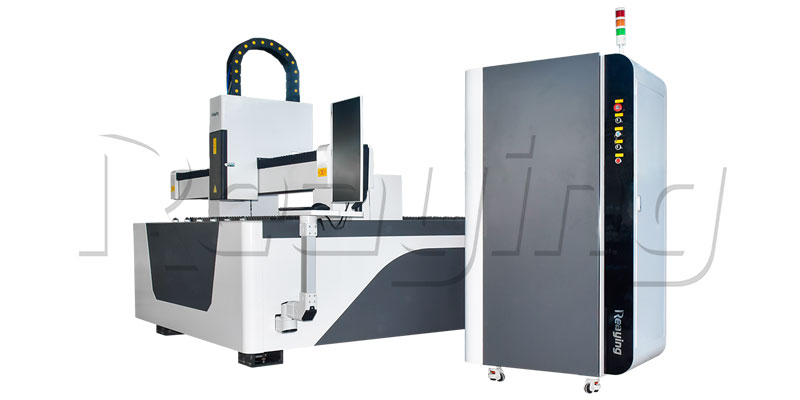

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More