The solution to removing burrs during the use of fiber laser cutting machine

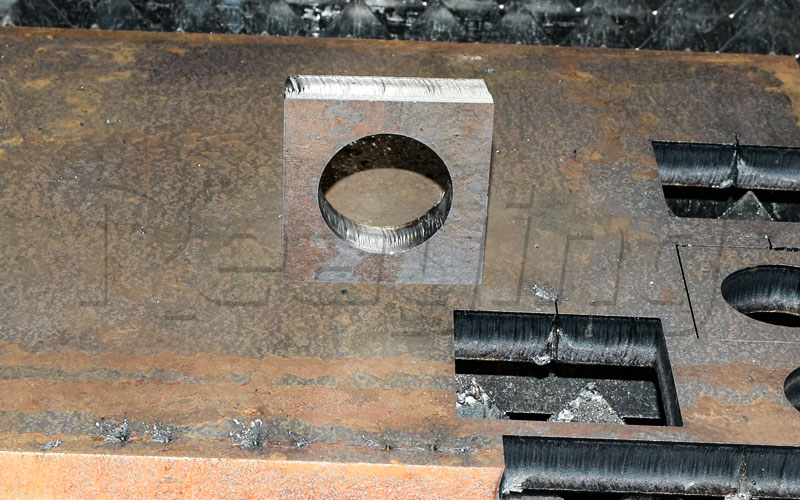

In the process of fiber laser cutting, sometimes irregular parts such as sharp corners and burrs at the transition of the workpiece surface are burrs. Burrs directly affect the dimensional accuracy, shape and position accuracy and surface roughness of the workpiece to be machined. When the laser cutting machine is processing the workpiece, the high energy generated by the laser beam irradiating the workpiece surface rapidly vaporizes and evaporates, so as to achieve the purpose of cutting. There are two main reasons for glitches:

First, the auxiliary gas is vaporized on the irradiated surface of the workpiece to blow off the slag on the surface of the workpiece. If auxiliary gas is not used, burrs will form on the cut surface after the slag cools. The equipment itself, parameter setting factors, daily use skills. Therefore, after customers buy a new fiber laser cutting machine, they must go through professional training before they can start using it.

The solution for removing burrs during the use of fiber laser cutting machine:

- The gas purity should be high, try not to use cylinder gas, because after two fillings, the gas will be wasted if the purity is not good. For example, when cutting stainless steel with a laser, it is recommended to use nitrogen as an auxiliary gas, which is a flame retardant gas. In the laser processing process, nitrogen not only prevents the explosion point phenomenon of laser cutting, but also the heated end face will not be oxidized instantaneously, and the cutting end face will be smoother and brighter. The auxiliary gas should be adjusted to a pressure of 12-15 kg. Nitrogen at this pressure will not completely prevent combustion and will quickly blow away waste impurities to remove burrs.

- Find a professional operator to debug the parameters of the metal laser cutting machine, and then you can successfully complete the cutting operation of the fiber laser cutting machine. Some parameters of the laser cutting machine will also affect the appearance of the slag, resulting in burrs in the fiber laser cutting machine, so the cutting parameters should be adjusted to the best. The gas parameters of the equipment are adjusted to the best, and the cut workpiece has no burrs, which makes the cutting of the fiber laser cutting machine more high-quality. Check if the laser cutter is working properly. If it is not normal, it needs to be repaired and maintained in time. If OK, check if the output value is correct.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More