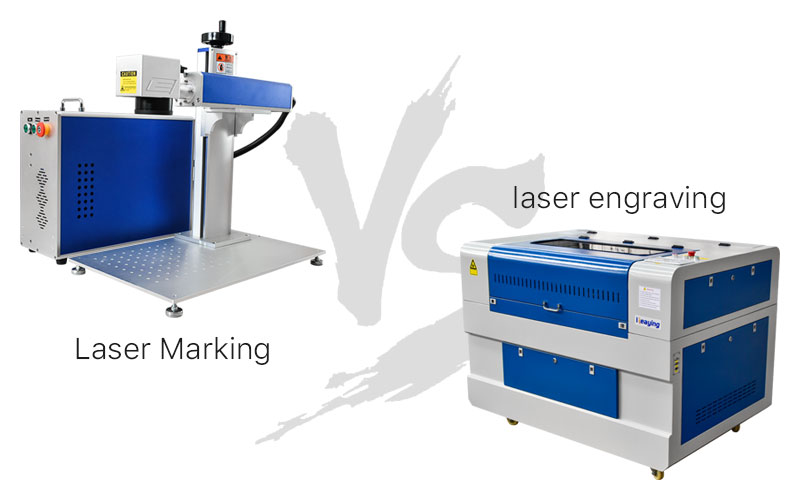

The difference between laser marking machine and laser engraving machine

With the development of laser technology, the types and performance of laser equipment are constantly improving and improving. At present, the common laser marking equipment on the market includes laser engraving machine and laser marking machine. Many friends said that these two machines feel similar. So, what is the difference between a laser marking machine and a laser engraving machine?

- The working principle is different

Laser marking machines use laser beams to make permanent marks on the surface of various materials. The function of marking is to expose the deep material through the evaporation of the surface material, or to “carve” traces through the chemical and physical changes of the surface material caused by light energy, or to burn part of the material through light energy to display the desired etching pattern and text .

A laser engraving machine is a laser device that uses the thermal energy of a laser to engrave and cut materials. Also known as laser cutting machine, laser etching machine, etc. - The laser used is different

Laser marking machine Laser marking machine is mainly divided into CO2 laser marking machine, fiber laser marking machine and ultraviolet laser marking machine. The service life of various lasers is different. For example, the service life of metal tube lasers is generally about 30,000 hours. Of course, the fiber laser marking machine laser has the longest service life, which can reach 100,000 hours.

Laser engraving machines can be divided into CO2 non-metal laser engraving machines and fiber optic metal engraving machines. The laser of the CO2 non-metal laser engraving machine is generally a carbon dioxide glass tube, and the life of the glass tube laser is generally 2000-10000 hours. The fiber laser can be used continuously for more than 10w hours. - Different applicable materials and different application industries

CO2 laser marking machine The laser marking machine is suitable for a variety of non-metallic materials and has a wide range of applications. A variety of materials can be permanently marked with high quality. Used in clothing accessories, pharmaceutical packaging, wine packaging, architectural ceramics, beverage packaging, cloth cutting, rubber products, shell nameplates, craft gifts, electronic components, leather and other industries. However, fiber laser marking machines can be widely used in metal products.

Laser engraving machines can be roughly divided into: non-metal laser engraving machines and metal laser engraving machines. Therefore, it can be used for both metal materials and non-metal materials, and the application range is very wide. For example, laser processing can be performed on non-metallic materials such as bamboo, wood, crystal, horn, cardboard, plexiglass, marble, cloth, leather, rubber, and plastic. Clothing, embroidery, upholstered toys, home fabrics, handbags, gloves, leather for the toy industry, leather cutting and surface engraving. Precision cutting of non-metal sheets such as acrylic boards, medium-density decorative boards, etc. in industries such as handicrafts, models, advertisements, decorations, electrical appliances, and plastics. - The processing depth is different

The laser marking machine only marks on the surface of the material, and the depth is very shallow, generally less than 0.5mm, while the laser engraving machine can mark very deep, ranging from 0.1mm to 100mm, and can penetrate deep into the object. Even if it is opened, the specific depth still depends on the material. - Different processing speed

The engraving speed of the laser engraving machine is generally the fastest cutting speed of 200mm/s, and the engraving speed is 500mm/s; the speed of the laser marking machine is generally three times the speed of the laser engraving machine. - Different processing techniques:

The laser engraving machine can be equipped with an electric lifting platform and a rotating shaft, which can engrave regular or irregular objects such as cylinders, special shapes, and spheres. Due to the stability control of the laser head and the optical path setting of the laser marking machine, the platform can adjust the focal length left and right, so it is mostly suitable for plane engraving. - Different prices

Different configurations, such as different lasers and different powers, will have different final prices. Generally speaking, laser engraving machines have deeper engraving depth and higher power. However, the printing depth of general laser marking machines is very shallow, and the laser power is low. For non-metallic laser engraving and cutting machines, the price of low-power laser marking machines is much cheaper than that of laser marking machines, but high-power laser engraving machines are also more expensive.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More