How to solve the fault of laser engraving machine laser output?

Laser engraving machine when encountered all kinds of faults do not panic, but there are a lot of problems are relatively simple, you can check yourself, perhaps after a hand repair, “paralysis” of the machine is back up and running.

Today’s question is: laser engraving machine laser output problem: no output or the output intensity of how to solve? After understand the general reason, hands-on ability of you give it a try! Major problems were small, small problem is no problem.

- focus lens pollution caused by weak output than ever before, why, with clean tools to carefully clean up, the problem can be solved. Also be careful of focusing is changed, sometimes when cleaning will be careful not to lead to occurrence of fine focus.

- laser output light path caused by the fault offset, the adjustment of course know adjustment method, if you do not know the words or do not own disorderly adjustment. So you can consult businesses how to adjust the optical path in the purchase after the training.

- State power laser power supply is normal, if not normal will cause the failure of laser output, specifically to check the equipment to work normally or not.

Other reasons: reflection lens is polluted, water cooling system circulation inspection, circulating water temperature is too high or too low. Laser tube to confirm that you want to replace the aging degree; work environment is too bad, for example, the temperature is too high.

Most the reason from the above view mainly is usual for laser engraving machine maintenance level, so that can not be ignored is that some small details. For these solutions if they understand, do it yourself can solve it yourself. If it is not, can not blindly treatment, still need to contact the merchant is responsible for resolving.

Laser engraving machine common fault and its treatment method

- how to save time

In signage products small size of mass production with the specifications of the X, the direction of maximum width should be less than 300mm, which can make the laser head to reverse speed, thus improve the speed. Bitmap in the engraving, may be appropriate to reduce the resolution, to accelerate the pace of. In addition, laser machining depth and power, speed is proportional to, which is the same power condition faster engraving depth is more shallow, whereas more deep, so you should try to improve the speed and power to shorten the time. - how to avoid waste

A red light positioning equipment standard general laser engraving machine. In the processing of irregular products, should be the first to use red light positioning observation carving position is accurate, and then formally processing. For not previously seen material, should follow the principle of power from low to high. - the machine without laser

The magnetic switch and circuit check the laser engraving machine cover, the front door with no loosening, shed (Shandong has a user, the first night, the machine from inside to outside clean, found the morning of the second day the machine does not emit laser, after examination is to clean the machine when the magnetic switch circuit loss caused by). Then check the reflection, focusing lenses have no problem (Beijing a user wiping reflex lenses, no screw fixing screw loosening, resulting in the lens, and cause no laser). If not the above reason, must and repair personnel contact, please do not self treatment. - large area signage engraving, cutting depth

This is because the laser light path is not caused by. As long as the optical path adjustment is on the line (with special training in the purchase). - carved font deformation

1) if the car pulley with serious wear and tear, causing head trolley loose, replace the pulley.

2) if the Y axis at the left and right sides of belt tension is not the same, six angle screw and tension is adjusted at the end of Y axis.

3) if the X axis on the left from the wheel wear, replace the wheel.

4) if the X axis motor fault, replace the motor.

5) if the fastening screws X axis motor and a belt pulley is loose, tighten the screws.

6) engraving machine carve, memory is bad or damaged. Reinstall the memory or replace the memory.

7) the computer interface to be set to SPP.

8) laser engraving machine data line to keep away from the interference source

9) with a socket, the best computer and laser engraving machine, in order to avoid potential difference. Sudden power cut in half for laser tube failure, can only return to factory repair.

10) laser engraving machine power gradually decay

First check the reflection lens and focusing lens is clean, light is not positive. If there is no problem, should be timely contact with the repair personnel.

11) in the large area of engraving and cutting, such as not appear in shades of materials. It must be the light path is not.

Laser engraving machine has the advantages of simple operation guide

Processing signage filing after processing position can be selected, and the use of software high-speed processing speed, strength and accuracy. Such as image processing, but also design the corresponding grid, after adjustment to the output frame, to determine the location of the workpiece on the table, and then placing the workpiece, the workpiece in place according to the output of software (print) button, and waits for the laser engraving machine engraving machine to receive files, files can be received after March red light positioning and press the start button (red light positioning: before processing formally open the machine cover, output files, press the start button, the laser tube does not emit laser, can observe the machining position is accurate, in order to avoid the waste generated due to inaccurate positioning), and then press the start key processing.

Matters needing attention

- the use of automatic focus, attention should be paid to automatic measuring focal rod must be tightened, otherwise the work table top to the laser head, and off the track.

- laser engraving machine at work, prohibit open the machine cover (cover and the front cover), otherwise it will stop the laser emission, affecting the quality of machining.

- the sign processing the workpiece, must open the exhaust and smoke device, to prevent dust pollution focus lens and the reflecting lens, otherwise it will affect the lens focusing and reflection, and thus indirectly affect the processing intensity, machining precision.

- wood processing, paper work, must pay close attention to the machining speed and strength, avoid the speed is too slow, high strength and flame. The flame will damage the focusing lens, the light impact strength, machining accuracy, or the machine will not be able to use.

- irregular workpiece for early adopters, must first red positioning, to determine the processing location are correct, otherwise easy to produce waste.

- easy deformed materials thin wood, cardboard and other processing, to adjust the deformation amplitude level is less than 1 mm, in order to avoid the focal length difference is too large, affecting the machining accuracy. Processing of paper to paper fixed, avoid displacement occurs when working. The cutting of paper, especially soft paper (paper, Mao Bianzhi), can be folded and placed in 15 – 20, water soaked, leveling, and then cutting. This can improve the work efficiency, and avoid the risk arising from the combustion of materials.

- the cutting, in order to make the workpiece holder from the work table 2 centimeters of above, avoid the laser reflected back to the workpiece damage, waste generated.

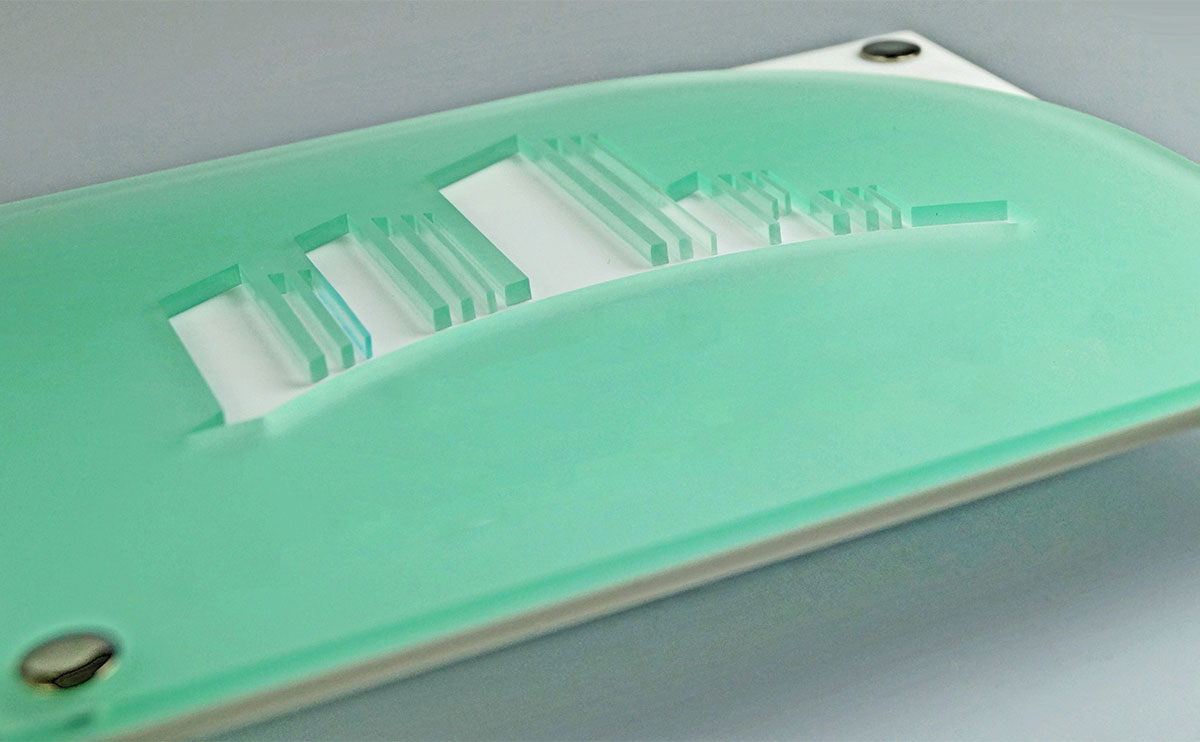

- reflection lens and focusing lens cleaning: two fingers to pinch reflex lens, camera lens with the other hand cleaning paper dipped in the cleaning liquid, gently shuffled through lens surface, prohibit the use of fingers oppression mirror to avoid scratches; or use cotton swabs dipped into the camera lens cleaning solution to wipe gently focusing lens until smooth.

- usually carved vector sign documents, resolution should choose a high number (500dpi or 600dpi); Chen file carving, resolution should choose low (500dpi rough mode or 300dpi). This carving effect will be very good.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More