How to install the laser engraving machine?

Today for everyone to share under the laser engraving machine installation steps:

- packing and inspection on appearance

Open the packing cases first to see whether the laser tube getting damaged, and check whether the parts is complete, the body appearance with and without scratches. - choose put position

Persons to be ventilated dry place, near the ground, try not to move the machine again, after debugging good or need to adjust the light path. - installation

A: buried A 2 mm diameter copper wire to below 1 meter, meet in processing power on the other end.

B: insert the control card microcomputer PCI slot, tighten the screws, then good, insert the USB data line encryption, pack good operating software and encryption dog driver.

C: will the tank filled with pure water, good water pump, connected in and out of the water and the air inlet pipe.Water cycle have to observe the laser tube in a few minutes without air bubbles, rotating laser tube to squeeze the bubble.

D: the laser tube water pipe and anode wires connect well, and then into the laser tube card five.The laser power and laser tube of Yin and Yang are very connected with cable.

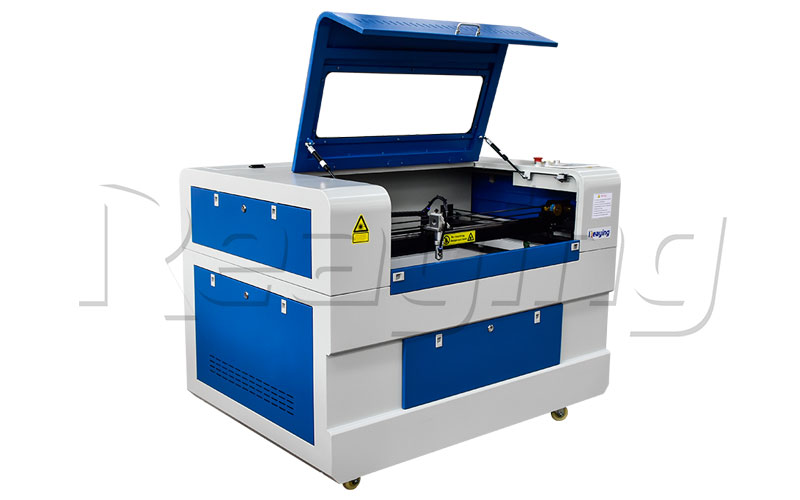

Laser engraving machine

Laser engraving machine has become the object of many enterprises to choose, that what happens when the laser engraving machine stand out from the traditional carving equipment?By now I analyzed one by one to you:

- laser engraving speed is quick

Laser engraving process simple and quick.Sculpture design in general, as long as through computer processing, then output to the laser carving mechanism for can, eliminate the tedious process of traditional carving technology, laser engraving is 100 times faster than the average engraving method above, and can ensure high repeat precision carving. - wide range of laser engraving

Laser engraving on non-technical materials for, such as glass, plastic, resin, and leather, rubber, wood, etc.;Laser can also be carving of the metal material, such as nickel, lead, steel, alloy plate;Laser can even higher refractoriness carving the case of hard and brittle materials, such as ceramics, quartz, glass, heat-resistant alloy, etc.;Laser can go deep into the inside carving material inside, such as crystal. - laser engraving consume less power

Compared with other way of carving, laser engraving adopted energy use very direct way, less energy conversion part, simple process, less protection link, and the fine carving, less waste of raw materials, at the same time can improve the work efficiency. - sculpture is easy to operate

Laser combined with automatic control technology, it is easy to realize automatic control process, a high degree of automation. - laser engraving quality

Laser engraving is a striking feature of high quality carving.Because the laser itself has high strength, good directivity and beam focusing spot is small, completely can do fine carving, carving, high resolution, can realize fine carving and cloud-like pattern.Because laser engraving don’t like traditional carving methods when in contact with the carved material, cutting head and DiaoKeJian are clean and no pollution, no adverse impact of the cutter and workpiece friction and carved the case material oxidation, deformation, thermal expansion effects are small.

Need Help!!!

Categories

Recent Post

Tag Cloud

About Reaying

Shandong Reaying Machinery Co., Ltd. is one of the leading laser machine manufacturers around the world since 2008 with a registered capital of 3 million yuan. It is a high-tech enterprise focusing on R&D...

Read More